How to properly use synthetic fiber in concrete?

Jan 19, 2024|

Jan 19, 2024| View:153

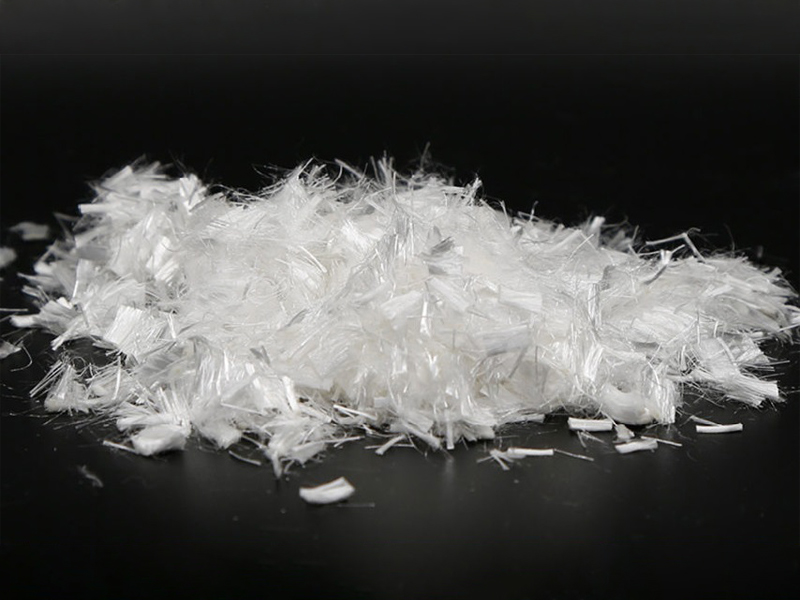

View:153Synthetic fiber for concreteis a versatile and innovative material that offers numerous advantages in construction applications. With its ability to enhance the performance and durability of concrete, synthetic fiber has gained popularity as a reinforcement solution. Understanding how to properly use synthetic fiber in concrete is crucial to maximize its benefits and achieve optimal results.

1.Advantages of synthetic fiber for concrete

The advantages of using synthetic fiber for concrete are numerous. Firstly, synthetic fibers act as a reinforcement material, increasing the tensile and flexural strength of concrete. This reinforcement helps to control cracking and improve the overall structural integrity of the concrete. Additionally, synthetic fiber can enhance the impact resistance and toughness of the concrete, making it more resistant to heavy loads and external forces. Furthermore, synthetic fiber offers better resistance to corrosion compared to traditional steel reinforcement, making it suitable for applications in corrosive environments.

2.Application of synthetic fiber for concrete

Synthetic fiber for concretefinds widespread applications in various construction projects. It is commonly used in industrial flooring, shotcrete applications, precast concrete elements, and overlays. The fiber can effectively control shrinkage cracking and improve the post-crack performance of concrete. It is also suitable for applications requiring high durability, such as bridge decks, tunnels, and pavements. Moreover, synthetic fiber is often used in decorative concrete applications, providing reinforcement while maintaining the aesthetics of the finished surface.

3.How to properly use synthetic fiber in concrete?

To properly use synthetic fiber in concrete, several factors need to be considered. Firstly, it is essential to determine the appropriate type and dosage of synthetic fiber based on the specific project requirements. Different fiber types, such as polypropylene, polyethylene, or nylon, offer varying benefits and performance characteristics. The dosage of synthetic fiber should be carefully calculated to ensure the desired reinforcement effect without causing excessive fiber balling or fiber congestion.

Secondly, the mixing process plays a critical role in achieving uniform distribution of synthetic fibers within the concrete matrix. It is recommended to use a high-quality concrete mixer to ensure proper dispersion. The mixing time and speed should be adjusted to allow sufficient fiber dispersion without damaging the fibers.

During concrete placement, it is important to ensure proper compaction to avoid fiber settling or segregation. Vibrating the concrete with appropriate equipment helps to achieve proper compaction and ensure uniform fiber distribution throughout the concrete mix.

It is worth noting that synthetic fiber for concrete is not a substitute for traditional steel reinforcement in all applications. In certain cases, a combination of synthetic fiber and steel reinforcement may be required to meet specific structural requirements. It is crucial to consult with structural engineers and experts to determine the most suitable reinforcement solution for each project.

4.Factors to consider when purchasing synthetic fiber for concrete

When considering the purchase of synthetic fiber for concrete, it is essential to partner with a reputable manufacturer or supplier. Quality and consistency of the fibers are crucial for achieving desired performance and ensuring long-term durability. Additionally, customized solutions may be available to meet specific project requirements, and consulting with experts can help in selecting the most suitable type and dosage of synthetic fiber.

Synthetic fiber for concrete offers significant advantages in terms of reinforcement, crack control, and durability. Proper usage of synthetic fiber involves selecting the appropriate type and dosage, ensuring proper mixing and compaction, and considering the specific project requirements. When seeking to utilize synthetic fiber for concrete, it is advisable to collaborate with experienced professionals to ensure the best results. Contact us today to explore the possibilities of customizing synthetic fiber solutions for your concrete projects.