0

0UHPC SPECIAL SYNTHETIC FIBER(POM)

ready mixed fibre reinforced concrete、Acetal Copolymer fiber for Ultrs-High Performance Concrete(UHPC),is a new plastic material for concrete construction engineering (see the GB/T21120-2018),Using the POM resin slices as its raw material ,this product is made through spinnig ,drafting ,surface treatment,etc.It has superior performance of high strength ,high modulus, high durability ,wide usage temperature range and little influence on workability.

Description

UHPC special synthetic fiber uses hydrophilic modification technology for its surface treatment It has excellent dispersibility in UHPC and has good bonding performance with cement matrix materials which can effectively reduce and inhibit UHPC plastic shrinkage drying shrinkage Micro-cracks caused by temperature changes and other factors significantly improve crack resistance toughening impact resistance fire and explosion resistance of UHPC

Application

l Building decoration exterior wall

l UHPC carved artwork

l Cement flower pot products

l Municipal road bricks etc.

steel fiber reinforced concrete advantages and disadvantages

Benefits

l No rusty

l Excellent dispersity

l Self compact

l Light and Artistic

l Colourful

Technical Information

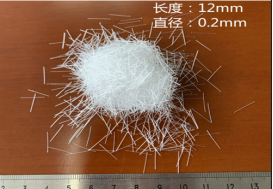

Fiber dimension | D:0.2mm;L:6/12mm |

Minimum Tensile Strength | >950Mpa |

Modulus | >12Gpa |

Elongation at break | <=30% |

Density | 1.4g/cm3 |

Acid&Alkali Resistance | Excellent |

Moisture Content | <=0.1% |

Appearance | Transparent monofilament |

Guidelines for use

Dosage:the usual dosing amount is 5.0/50.0kg/m3(the corresponding volume dosing amount is 0.4/4.0%).

Length;The length of UHPC should be 6-12mm,according to different thickness of components.

Stirring:After mixing the UHPC powder and water to make the slurry evenly,add the fibers

Curing:The construction and curing process of UHPC after fiber is exactly the same as the system without fiber

Packing:

10 or 20/kg big bag ,700/pallet,7000kg/20’container,14000kg/40’container.